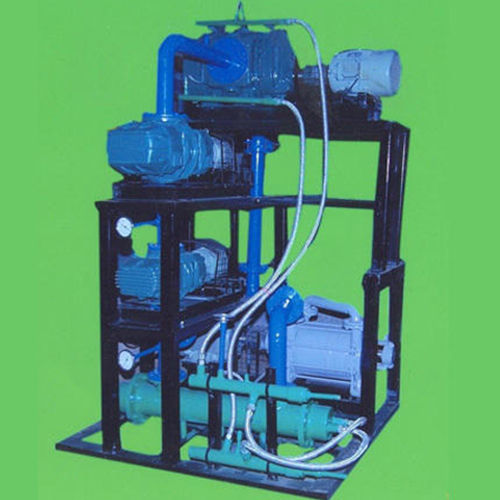

Booster Vacuum System

100000.00 INR/Piece

Product Details:

- Product Type Vacuum Booster

- Color Blue

- Usage Industrial

- Material Steel

- Processing Type Standard

- Condition New

- Power Mode Electric

- Click to View more

X

Booster Vacuum System Price And Quantity

- 2 Unit

- 100000.00 INR/Piece

Booster Vacuum System Product Specifications

- Standard

- Vacuum Booster

- 1 Year

- Blue

- Steel

- 20 Kilowatt (kW)

- Electric

- New

- Industrial

Booster Vacuum System Trade Information

- 10 Unit Per Day

- 1 Days

- Chandigarh Andaman and Nicobar Islands Andhra Pradesh Assam Karnataka Madhya Pradesh Mizoram Arunachal Pradesh Bihar Goa Haryana Jammu and Kashmir Maharashtra Nagaland Odisha Jharkhand Kerala Pondicherry Telangana Tripura Uttar Pradesh West Bengal Uttarakhand Himachal Pradesh Manipur Meghalaya South India Central India East India West India Punjab Rajasthan Sikkim Tamil Nadu Daman and Diu Dadra and Nagar Haveli All India Lakshadweep Delhi Gujarat North India Chhattisgarh

Product Description

We have specialization in offering the most advanced and highly reliable Booster Vacuum System . These boosters are demanded to handle large gas volumes in low positive pressure applications. Its free rotation mechanism is powered by shaped lobes that are fabricated from premium grade material. Our offered vacuum booster system can be ordered at market leading price from us.

Booster Vacuum System Specification:

- Max. Power M (bar) At 50Hz :- 100 To 55

- Max. Power M (bar) At 60Hz :- 75 To 45

Booster Vacuum System Features:

- Boosting Capability

- High Pumping Speed

- Energy Efficiency

- Compact Design

- Low Noise and Vibration

- Reliable Operation

- Compatibility

- Control and Monitoring

- Maintenance and Serviceability

Booster Vacuum System Benefits:

- Booster vacuum systems contribute to energy efficiency by optimizing the operation of the primary pump.

- It provides increased pumping speed and improved vacuum levels that can enhance process efficiency in several industrial applications.

- It offers advanced control and monitoring features.

- It improves the overall reliability of the vacuum system.

Booster Vacuum System - FAQs:

Q: What is a booster vacuum system?

A: A booster vacuum system is a combination of a primary vacuum pump and a vacuum booster that work together for enhancing the pumping capacity and vacuum performance of the system.

Q: How does a booster vacuum system work?

A: A booster vacuum system works by using a positive displacement pump to increase the pumping speed of a primary vacuum pump. The booster pump compresses vapor or gas, transferring it to the primary pump at a higher pressure and velocity. The primary pump then evacuates the gas or vapor further, taking advantage of the increased kinetic energy provided by the booster pump. This combined action enhances the overall pumping capacity and efficiency of the vacuum system, and hence allows for faster evacuation and improved performance in numerous applications.

Q: What are the benefits of using a booster vacuum system?

A: Some benefits of using a booster vacuum system include improved vacuum level, increased pumping speed, enhanced system efficiency, reduced evacuation time, and the ability to handle large volumes of gas or vapor.

Q: Where are booster vacuum systems used?

A: Booster vacuum system finds applications in different industries such as pharmaceuticals, chemical processing, automotive, food and beverage, aerospace, and more.

Q: Can a booster vacuum system be customized for specific applications?

A: Yes, booster vacuum systems can be customized to meet specific application requirements on the basis of desired vacuum level, gas compatibility, pumping speed, size, and control mechanisms.

Q: What maintenance is required for a booster vacuum system?

A: Regular maintenance for a booster vacuum system includes tasks such as checking and replacing seals, monitoring oil levels (if applicable), inspecting and lubricating moving parts, and ensuring proper cooling and ventilation.

Q: Can a booster vacuum system handle corrosive gases or liquids?

A: The ability of a booster vacuum system to handle corrosive gases or liquids depends on the specific components and materials of construction. For handling corrosive liquids or gases, it is important to select the appropriate booster pump and ensure proper protection and maintenance.

Q: Where can I find technical support or assistance for a booster vacuum system?

A: Manufacturers of booster vacuum systems provide technical support and assistance. They can provide guidance on system selection, operation, installation, and maintenance to ensure optimal performance and address any concerns.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email