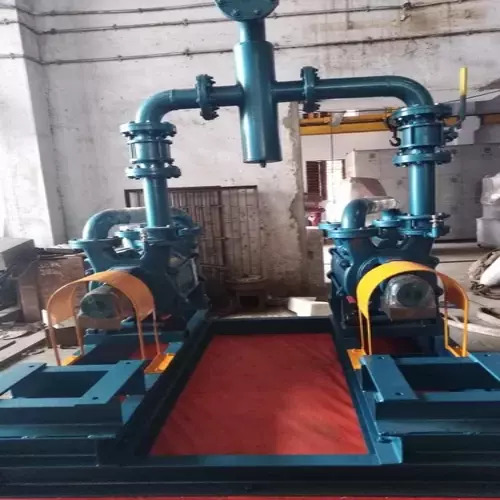

Double Stage Water Ring Vacuum Pump

50000 INR/Piece

Product Details:

- Color Blue

- Usage Industrial

- Theory Vacuum Pump

- Material Cast Iron

- Power Electric

- Pressure Medium Pressure

- Click to View more

X

Double Stage Water Ring Vacuum Pump Price And Quantity

- 1 Piece

- 50000 INR/Piece

Double Stage Water Ring Vacuum Pump Product Specifications

- Vacuum Pump

- Industrial

- Blue

- Medium Pressure

- Electric

- Cast Iron

Double Stage Water Ring Vacuum Pump Trade Information

- 10 Piece Per Day

- 1 Week

Product Description

Water Ring Vacuum Pump Double Stage designed and developed by our company is commonly used in wide range of industrial sectors such as oil & gas, chemical, mining, food, textile, mining, and marine. It is installed with a robust energy efficient pump that is capable to operate at variable pressures. The sturdy cast iron body of this industrial machine provides high strength and rigidity to bear extreme working conditions. It requires a single phase alternating voltage for controlled and safe functioning. The offered product can be delivered to our customers with a supply ability of 10 units per day.

Water Ring Vacuum Pump Double Stage Specifications:

- Phase: Single

- Number of Stages: Double Stage

- Material: Cast Iron

- Brand: Leelam Industries

- Automation Grade: Automatic

- Usage/Application: Industrial

Water Ring Vacuum Pump Double Stage Features:

Some of the key features of a double stage water ring vacuum pump are:

- Two-Stage Design

- Higher Vacuum Levels

- Increased Pumping Capacity

- Efficient Operation

- Robust Construction

- Low Noise and Vibration

- Easy Maintenance

- Versatile Applications

- Reliable Performance

- Safety Features

Water Ring Vacuum Pump Double Stage Benefits:

- The Double Stage Liquid Ring Vacuum Pump has high maximum pressure. Unlike single stage water ring vacuum pumps, these pumps offer better efficiency. They are more effective at higher vacuum levels and can also be utilized in pharmaceutical and chemical installations. These pumps are available for a wide range of applications.

- Their compact design, reduced power consumption, and variable discharge port makes them ideal for continuous operation. The pumps have lower exhaust pressure and greater efficiency. If deep vacuum is a required, then this is a great solution. These pumps have the highest level of efficiency and are ideal for most industrial environments.

FAQ about Water Ring Vacuum Pump Double Stage:

Q: What is a double stage water ring vacuum pump?

A: A double stage water ring vacuum pump is a type of vacuum pump that uses a water ring as the working fluid for creating a vacuum. It consists of two stages, each with its own water ring and impeller, which helps in achieving higher vacuum levels and increasing pumping capacity as compared to a single stage pump.

Q: How does a double stage water ring vacuum pump work?

A: The working of this pump is similar to a single stage water ring vacuum pump. Water or another suitable liquid is used as the working fluid, that forms a water ring inside the pump. The rotating impellers create a centrifugal force that compresses the gas inside the pump and pushes it towards the exhaust. As the gas moves through the stages, it undergoes further compression, and this results in a higher vacuum level.

Q: What are the advantages of using a double stage water ring vacuum pump?

A: Some advantages of double stage water ring vacuum pumps are:

- Higher Vacuum Levels

- Increased Pumping Capacity

- Energy Efficiency

- Versatility

- Reliable Operation

Q: What are the typical applications of double stage water ring vacuum pumps?

A: Double stage water ring vacuum pumps find applications in several industries, such as:

- Chemical and Pharmaceutical

- Food and Beverage

- Power Generation

- Environmental

- Plastics and Packaging

- Pulp and Paper

Q: Are there any maintenance requirements for double stage water ring vacuum pumps?

A: Yes, double stage water ring vacuum pumps require regular maintenance. This includes checking and maintaining proper water supply, inspecting and replacing worn out seals, monitoring and adjusting pump performance, and ensuring cleanliness of the system. Scheduling routine inspections help in ensuring optimal performance and longevity of the pump.

Q: Can a double stage water ring vacuum pump handle liquids?

A: Double stage water ring vacuum pumps are designed for handling gases and vapors primarily but they can also handle small amounts of liquid carryover. It is generally recommended to separate liquids from the pumped gas before entering the pump in order to avoid damage to the internals.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free